National unified service hotline:0757-26616782

中文National unified service hotline:0757-26616782

中文Please enter keywords for search

Foshan Zhongshun Water Treatment Technology Co., Ltd

Tel: 0757-26616782 26628076

Email: sdzs@sinozs.com

Website: liaosa.cn

Official account: zs water

Address: No. 3 East Hongye Road, Ronggui Rongqi Avenue, Shunde District, Foshan City, Guangdong Province

The continuous water softener is the latest product developed by our company based on years of production experience. It inherits the advantages of continuous operation of the flow bed and thoroughly improves the control performance of traditional equipment, making the equipment operation performance more stable and reliable.

SRL continuous water softeners are divided into two forms: single stage exchange and double stage exchange. The single-stage exchange SRL1 series is suitable for softening water treatment in low-pressure boilers, textiles, printing and dyeing, and circulating cooling water supply. The two-stage exchange SRL2 series is suitable for softening high hardness water or treating extremely low hardness softening water in medium pressure boilers.

Equipment advantages:

● Long term continuous operation, without any issues of running cycle pauses or water quality fluctuations.

● Low operating costs, low consumption of regenerants, low self consumption of water, and sufficient production of soft water.

● Automatic salt dissolution and filtration, without the need for a salt tank, and avoiding the heavy labor of manual mixing.

● The equipment is more compact, occupies less land, is easy to install, and is easy to operate and maintain.

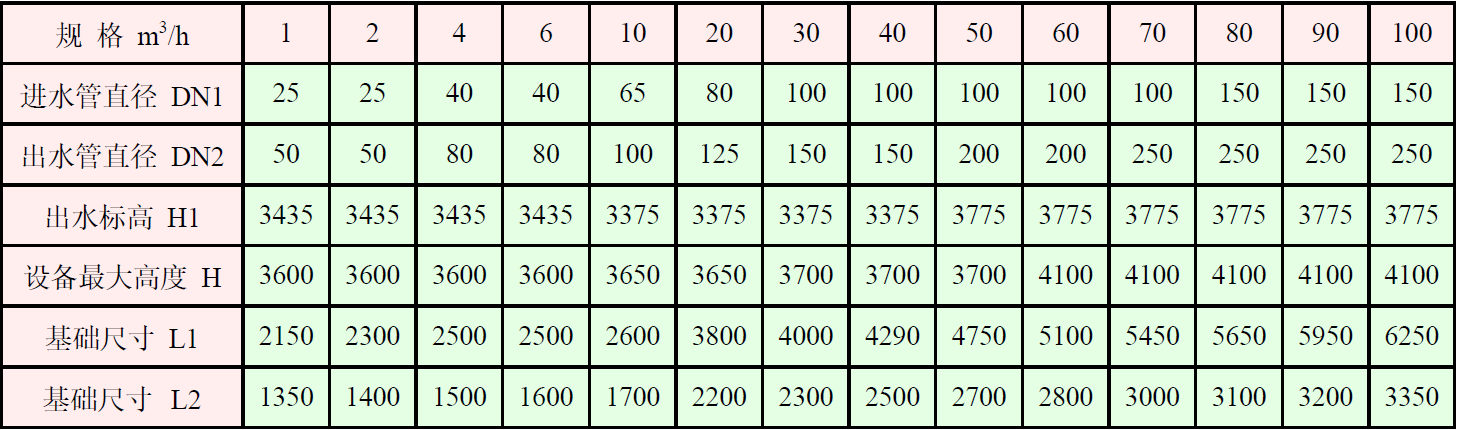

Main technical parameters:

Precautions:

1.Before installing the equipment, users should arrange the platform of the equipment to be at least 100mm above the ground, and set up drainage ditches around it to timely discharge wastewater.

2. If the hardness of the raw water exceeds 250mg/L, or other physical and chemical indicators cannot meet the requirements for equipment inflow, water quality information can be provided, and both parties can negotiate to design separately or use other equipment produced by our company to achieve the best treatment effect.

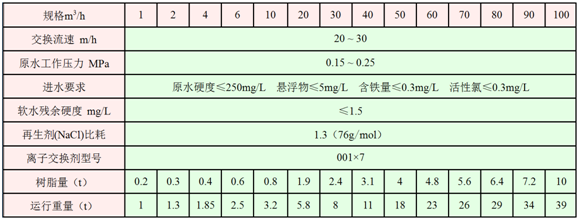

Process schematic diagram:

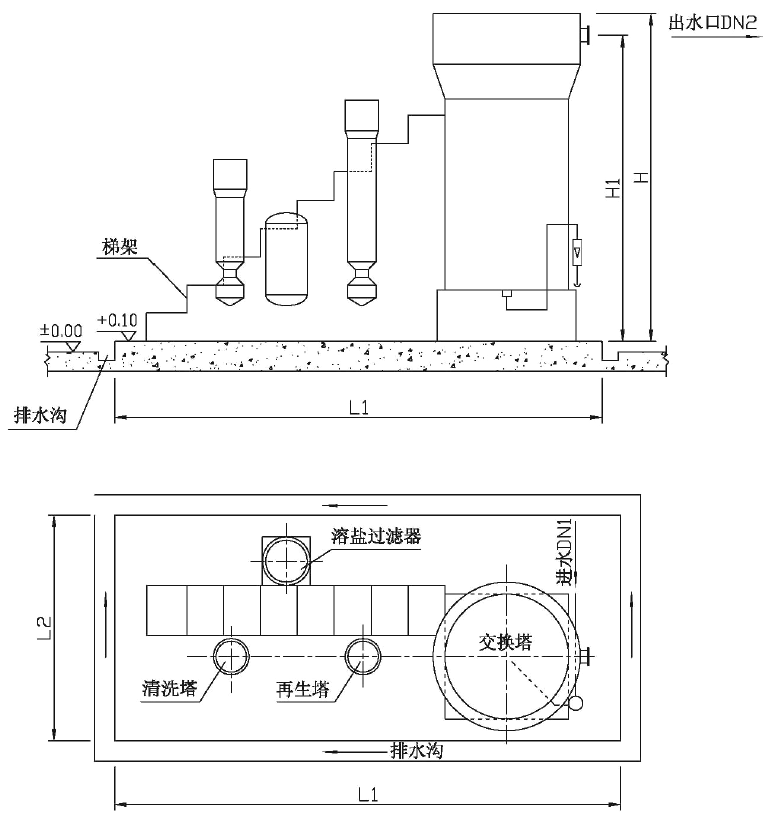

Layout: